In this article, we are going to give you a comprehensive guide on starter motor parts and functions.

A starter, also commonly referred to as a starter motor is a mechanical part in a vehicle that is designed to rotate an engine. A bad starter motor and its components often cause your vehicle to not start.

So it’s wise to get familiarized with starter motor parts and functions. The starter motor has more than a dozen small parts but we can start with the most important ones.

What is the starter in a car?

A car starter is an electric motor that cranks or turns over, a car’s engine to start it. The term starter motor refers to the electrical motor that is used to start a petrol/gasoline internal combustion engine. Car starters are usually located behind the engine, under the intake manifold.

It is an electric motor that has its power source and is buried in the engine compartment. The starter motor receives a signal from the ignition key (or push-button in newer cars), and it then rotates a small gear called the pinion which meshes with larger teeth on the engine’s flywheel.

Most passenger car engines have 12 volt electrical systems, so they need large amounts of current at low voltage. In contrast, most 24-volt truck engines require large amounts of current at high voltage. The starter must be able to deliver this current while producing relatively high torque (turning force) to crank the engine.

This requires larger components than those found in most other electric motors, such as steel laminations for the magnetic circuit, cast iron for the housing and rotor shaft, and heavy-duty bearings to support the rotating parts.

What does the starter look like?

If you happen to be under the hood and you want to find out where your starter is, look for a cylindrical object that will be near the engine block. Look for the location of the smaller cylinder which is fitted next to the cylinder-shaped starter. Here’s a video to illustrate the different starter motor parts and functions:

Starter motor parts and functions

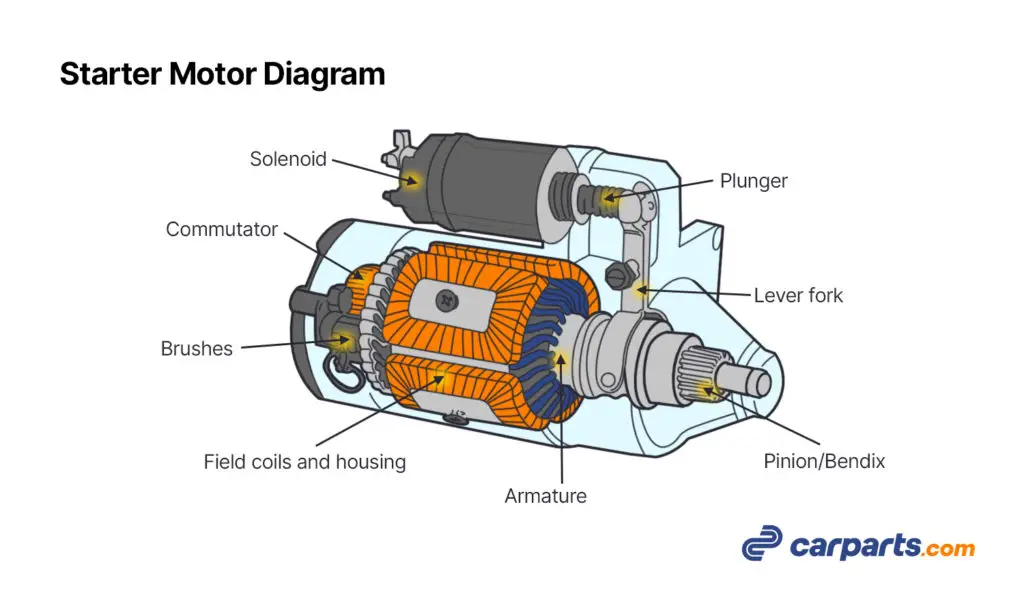

The starter system in a car has two main components; the starter and the starter solenoid. The starter is responsible for the actual spinning of the engine, while the solenoid supplies the power to do so. Aside from these components, below are the 7 important starter motor parts and functions that you should know:

1. Starter motor solenoid

A starter solenoid is an electromagnet that activates the starter motor of a vehicle’s engine. It is typically attached directly to the starter motor. Most modern vehicles also utilize a starter solenoid to engage the starter pinion with the ring gear.

The solenoid contains two coils of wire wrapped around a moveable core. The solenoid is a switch that connects the starter motor to the vehicle’s battery.

2. Armature

The armature is a power-producing component of the starter motor and converts electricity to mechanical energy. Armatures in starter motors are coils that form a magnetic field as current runs through them.

The starter motor is mounted on the driveshaft and supported by bearings. It has a soft iron core that coils of wire are wrapped around numerous times.

3. Drive lever

The drive lever is a fork-shaped component that serves to move the pinion gear. It connects the plunger to the pinion gear. The drive lever is attached to a rod-shaped component known as a shift fork or shift lever.

The drive lever pivots at one end and has an axial shaft at the other end. This axial shaft is connected to the plunger pressed against the pinion gear.

4. Pinion gear

It is connected to the armature assembly towards the flywheel gears. A pinion is a small mechanism containing gear and springs.

The engine engaged immediately when the starter was engaged by extending the flywheels’ gear to contact the engine’s teeth. The flywheel is a source of power that spins and generates rotational motion in an engine.

5. Yoke and pole core

A yoke is a part of the starter motor that houses the winding for both the poles and the field coils. It also acts as the body for starter motors, with a cylindrical shape.

The metal pole is the base of a yoke, which attaches to the shaft on either side. The inside of a pole core is where field coils are wound for pickup to increase magnetic fields when you have an electric current running through them.

6. Field coils

The field coils are held within a housing with screws. As they consist of two or more coils connected in series, individual windings are wound at right angles to one another and connected through the casing of the magnet.

When power enters these coils, they turn into electromagnetic fields that rotate the armature.

7. Plunger

The plunger’s movement causes the starter drive gear to interact with the flywheel ring, and this is what turns the motor.

The hold-in coil generates a weaker magnetic field to hold the plunger in place, saving battery power. In turn, most of the battery’s life is kept for starting the car.

How does the starter motor work?

The starter motor functions by converting electricity to mechanical energy. It’s a hand-crank device that is used to start the engine in your car, truck, or another vehicle when you turn the ignition key.

Starter motors are typically located between the engine and transmission on the front of an automobile.

What are the types of starter motors?

There are five types of starter motors, namely:

DD – Direct Drive

The direct drive starter motor also referred to as the DD, is the most common starter motor type. It is a solenoid-operated unit that comes in different applications and construction designs.

PLGR Planetary Gear

Planetary gear motor starters are part of the permanent magnet starter motors that quickly replace the direct-drive ones. The starter motor transfers the power from the pinion shaft to the armature. It spins at more speed and torque.

PMGR Permanent Magnet Gear Reduction

This starter type has been designed to provide less weight, easy construction, and generate less heat. Permanent magnet gear reduction starter motors depart from the typical field coil starter motor.

PMDD Permanent Magnet Direct Drive

This starter motor avoids rotor winding and mechanical energy losses associated with gearboxes and couplings. The unit can generate rotational speed, resulting in increased mechanical energy transformation.

OSGR Off-Set Gear Reduction

This type of starter uses an internal gear set to increase torque. This setup has the drive gears and motor rotating at different axes, which helps with power.